We Can’t Foreclose Grubbing Analysis

In logistics, we can still copy much of the 1930’s targeted organizing strategies, but we need a more sophisticated understanding of distributional relations and technologies. The death of chokepoint analysis has been greatly exaggerated.

In a recent Substack post, Eric Blanc argues that increasing decentralization and downsizing trends in workplaces and in residential life mean that “we can’t copy 1930s union targeting strategies.”

US labor’s big breakthrough in the 1930s was rooted in a centralized political economy far different from our own. Industries tended to be clustered in a relative handful of regions and cities. Workers tended to be concentrated in dense working-class neighborhoods adjacent to their jobs. In the largest corporations, though not necessarily elsewhere, jobs tended to be in massive factories. And due to the tightly bound nature of their assembly line and production systems, strikes by even a minority of well-positioned workers could relatively easily shut down their factory and dependent production chains.

Blanc is right to question how well-documented patterns of social and residential atomization are challenging traditional labor organizing strategies. With less dense neighborhood, familial, recreational, and social networks, the tipping point where a union drive starts moving by its own momentum becomes harder to reach. With dispersed workplaces and increasing dominance of the service sector, the organizational lattice provided by work becomes patchier.

If the social infrastructure that drives unionization is falling apart, it’s no surprise that union membership continues its slow asphyxiation—despite record press and popularity.

Blanc goes further than this, however: it is not simply that we can no longer target the big factories surrounded by dense working-class neighborhoods, but furthermore that the entire strategic chokepoint analysis that informed CIO organizers in the 1930s and fuels some advocates of supply chain organizing, like Kim Moody and John Womack, today leads us down the wrong path, toward an undue privileging of the logistics sector as strategically central. By taking “a closer look under the industrial hood,” Blanc argues that there is no sense in trying “to replicate the old hyper-targeted industrial strategy of the Communists and CIO.” But his cursory examination does not actually reckon with what’s under the hood, and with a superficial assessment of the issues there, his diagnosis that the “strategic organizing” perspective is misguided is not only underevidenced but also somewhat dangerous. In a moment of rapid revolution in logistics structures and technologies, one where new vulnerabilities are appearing but without a labor movement adequately able to keep up with them yet, we should be wary of judging and dismissing that which we do not understand.

The Logistics Workplace

Kim Moody has argued that the logistics industry presents labor today with a similar kind of opportunity that industrial manufacturing presented in the 1930s: high concentrations of workers in large workplaces, growing industry, drawing from a common exurban residential labor market, and occupying a position in today’s “just in time” economy that involves a great deal of leverage over firms that rely on globally-extended supply chains and decentralized, delivery-based retail markets. In other words, workers in logistics have both favorable “associational” situations and important “positional” power derived from where they are situated in the work process and in the economy.

Blanc’s essential counter to Moody is that workplaces across the board are getting smaller and more dispersed, even in logistics. But his numbers don’t tell the whole story. To arrive at his claim, Blanc divides the total number of workplaces for the eight largest US employers by the total number of workers to arrive at an average number of workers per site. According to his data, there are more than 5,000 UPS workplaces with an average of 81 workers. However, one can only arrive at this number of UPS workplaces if you count “UPS Stores,” which are not directly owned by UPS and are not integrated at all in the company’s logistics and parcel delivery operations as anything more than points for package drop-off and pick-up. In reality, there are around 2,000 UPS “Centers” (Centers are UPS’s term for units that dispatch the familiar brown package-trucks on delivery routes). The majority of those Centers are housed in multi-Center buildings. The majority of UPS workers work at the 100-200 large “Hubs” that employ more than 500 workers.

The same basic situation holds for the data on Amazon and Walmart. Both corporations also operate many different types of facilities with different concentrations of workers, different labor process technologies, and different degrees of strategic importance to the operation.

Firm-specific data doesn’t capture the whole picture of concentration in the transportation and warehousing industry. The immediate environment is just as important as what happens inside the firm. Logistics firms in many areas rely on “cluster” organization, which concentrates dozens of firms with similar operations in the same location. These workers often share as many contexts for interactions as workers in different departments and shifts within the same firm. Giant logistics parks, like AllianceTexas in Fort Worth (30,000 logistics workers), CenterPoint Intermodal Park and related properties around Chicago (40,000+ logistics workers), or new developments in the Loop 303 area on the western fringe of Phoenix, each concentrate tens of thousands of warehouse workers, package and freight truck drivers, and logistics specialists.

Clusters are an increasingly favored tool in the economic development toolkit for government officials and supply chain managers. New federal funding makes cluster strategy even more likely to see continued expansion in quantity and in scale in the coming decades.

The Amazon Case

Blanc refers to the work of Nantina Vgontzas to argue that there are significant constraints on workers’ associational and positional power within Amazon’s distribution network. In this account, new technology, diffusion, and dispersion enable an unprecedented level of resilience in Amazon’s network; executives can basically switch off facilities with the flip of a button and still keep the operations humming along. But Vgontzas’ work is focused on Amazon Fulfillment Centers, which are only part of their organizational ecology—and one that, at least in their classic form, may eventually be a casualty of Amazon’s pivot to a “regionalization” strategy.

To consider just one other example: in Amazon’s network, the positional power of workers in the “last mile” Delivery Stations is increasing as Amazon ratchets up efforts to wean itself off of reliance on UPS and other parcel carriers for deliveries. Warehouse workers who handle packages received at loading docks and sorted on belts before being loaded into delivery trucks and the drivers themselves are both crucial to Amazon’s success in their ongoing war on CEP market leaders. These jobs are also not currently threatened by the futuristic automation and robotics in Fulfillment Centers that are often written about by journalists.

Associationally, Amazon delivery drivers operate out of the same industrial corridors and logistics parks that house major UPS facilities. Drivers are painfully aware of the vast disparities between the wages, benefits, and conditions they receive from Amazon subcontractors compared to their peers at UPS. In addition, last-mile Delivery Stations by nature must be located close to the urban population centers they serve. Workers are recruited from a labor pool more favorable to unionization from a macro-social perspective. As Vgontzas argues, and Blanc endorses, coordination and scaling beyond a few workers on a key production line will be necessary. But the decentralization is relative and quantitative, not absolute and paradigmatic. Organizing a few stations could in theory set off the kind of “chain reaction” that union organizers in the 1930s successfully achieved. The new NLRB rule on joint-employment status may open the door to organizing drivers employed by the various “Delivery Service Provider” (DSP) subcontractors across entire Delivery Station buildings. If so, the Teamsters Union, which is currently awaiting a ruling on joint-employment for workers at a DSP in Palmdale CA, is well positioned to get the ball rolling organizing these workers.

Known Unknowns

If labor scholars are going to draw massive conclusions about strategy and organizing investments from industry analysis, it has to be a much more thoroughgoing one than Blanc engages in in order to reject Moody’s emphasis on logistics. What’s detailed above is really just a small glimpse into the reality beneath that “industrial hood,” and the employment structure, technologies, and distributional flows are changing all the time.

This gets to ultimately the more important error involved in the dismissal of Moody, Womack, and others’ desire for strategic prioritization. Understanding where the industrial chokepoints are today requires what Womack calls “grubbing analysis,” which involves tracing the different types of labor and technology used at every stage of a particular operation in order to understand the seams that knit the firm’s services together into a giant profit-producing whole.

There’s a ton we simply don’t know about the seams in technical processes today. No doubt the 1930s strategy of seizing the large factory with the sprawling machinery in a neighborhood where everyone knows about and hates the speed-up is not so applicable today. But that does not mean that there are not strategic chokepoints. Blanc’s brief look “under the industrial hood” makes it appear like there’s nothing interesting to see there, thus foreclosing the difficult work of pursuing strategic organizing analysis today. He cautions near the end of his article against throwing the baby out with the bathwater—for him, the grassroots approach of Great Depression-era organizing. But in concluding from the changed spatial dynamics since the 1930s that logistics holds no special place of importance in labor strategy, he has thrown out a different baby, and one we can ill afford to do without in the coming years.

■

Scott Jenkins is a visiting scholar at Arizona State University's Center for Work and Democracy.

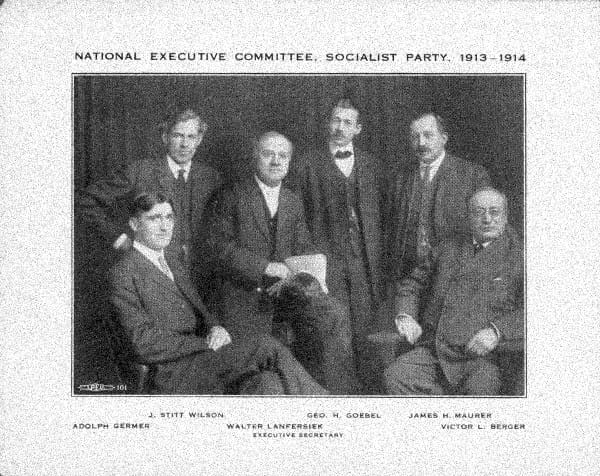

Benjamin Y. Fong is the author of Quick Fixes: Drugs in America from Prohibition to the 21st Century Binge, and the host/producer of Organize the Unorganized: The Rise of the CIO.